GYTC8S FIG 8 Multi Tube ARMORED FIBER OPTIC CABLE SPECIFICATION

Video

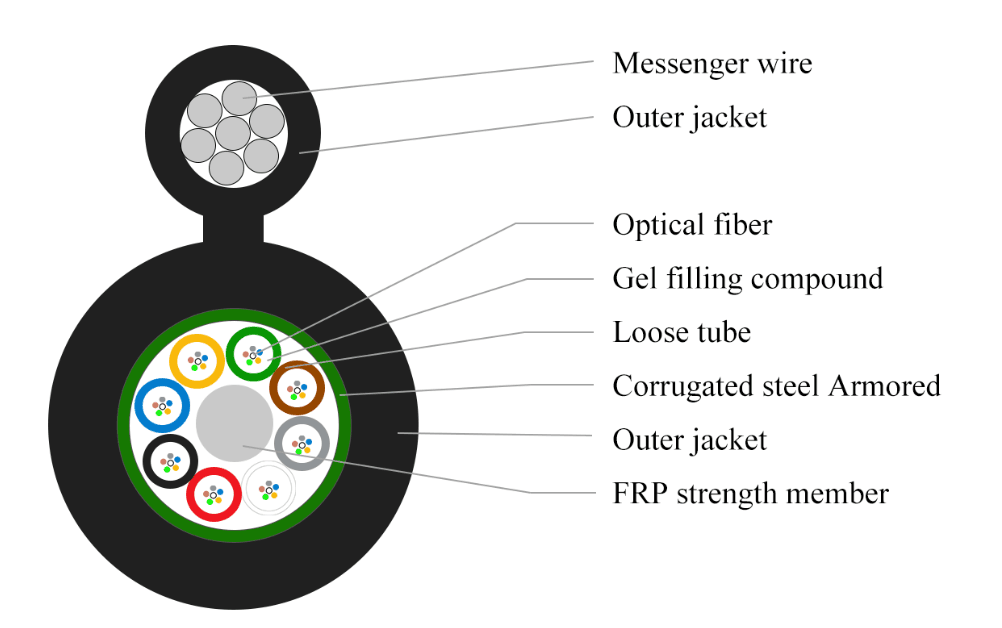

Cable Design

Structure Construction

Tube: SZ strands multi tube

Water block:Gelly filling compound in tube and water block yarn and water swellable tape triple protection

Reinforcing: High modulus Steel Armored tape

Sheath: UV stabilised polyethylene in

Messenger wire :High strength 7strands Galvanized steel wire

Features

| Part code | JH-GYTC8S XXXF | ||||

| Number of Fibers | Unit | 12/24/36/48 | 72 | 96 | 144 |

| Number of fiber in tube | Nos | 6/6/12/12 | 12 | 12 | 12 |

| Number of loose tube | Nos | 2/4/3/4 | 6 | 8 | 12 |

| Number of dummy filler | Nos | 3/1/3/1 | 0 | 0 | 0 |

| Central strength member | Material | FRP | FRP | FRP | FRP+ PE Coated |

| Loose tube | Material | PBT | |||

| Messenger wire | Material and size | 7strands Galvanized steel wire 0.9mm*7 | |||

| Outer sheath | Material | PE | PE | PE | PE |

| Cable nominal Diameter | MM ±0.2 | 9.0*16.7 | 9.5*17.2 | 11*19 | 12.8*20.5 |

| Cable nominal weight | Kg/Km ±5 | 105 | 115 | 130 | 155 |

|

Max. working tension |

N | 2100 | 2400 | 2600 | 3000 |

| Max. crush resistance | N | 2000 (Short term) / 1000 (Long term) | |||

| Min. bending radius | At full load 20 x Cable OD (including poles) At no load 15 x Cable OD | ||||

| Temperature range | Installation -0 -> +50 Operation -10 -> +70 | ||||

Optical Characteristics SINGLE MODE G652D

| Mode Field Diameter @ 1310 nm | 8.7-9.5 mum | ||

| Mode Field Diameter @ 1550 nm | 9.8-10.8mum | ||

| Cladding diameter | 125.0 ±± 0.7mm | ||

| Core/cladding concentricity error | 0.6 um | ||

| Cladding non-circularity | 1.0 % | ||

| Refractive index profile | Step | ||

| Design | Matched cladding | ||

| Primary coating material | UV curable acrylate | ||

| Primary coating Diameter | 235-250um | ||

| Optical Characteristics | |||

| Attenuation | @ 1310nm | £ 0.36 dB/km (cabling) | |

| @ 1383±3nm | £ 0.34 dB/km | ||

| @ 1550nm | £ 0.22dB/km (cabling) | ||

| Dispersion | @ 1288 ~ 1339nm | £ 3.5 ps/nm×km | |

| @ 1550nm | £ 18 ps/nm×km | ||

| Zero dispersion wavelength | 1300 – 1324 nm | ||

| Dispersion slope at zero dispersion wavelength | £ 0.092 ps/nm2×km | ||

| Cabled cut-off wavelength (lcc) | £ 1260 nm | ||

| Polarization mode dispersion link value | £ 0.2 ps/√km | ||

| Mechanical Characteristics | |||

| Proof stress level | ≥0.69 GPa | ||

| The loss increase of 100 turns of fiber loosely wound with | £0.05dB (at 1550nm) | ||

| 25mm radius | |||

| Effective group index of refraction Neff | 1.466(at 1310nm) | ||

| Effective group index of refraction Neff | 1.467 (at 1550nm) | ||

Identification

The fibers shall be marked by a coloured coating with 12 different colours according to EIA/TIA 598:

Fibre #1: Blue Fibre #7: Red

Fibre #2: Orange Fibre #8: Black (natural with being marked

Fibre #3: Green Fibre #9: Yellow

Fibre #4: Brown Fibre #10: Violet

Fibre #5: Grey Fibre #11: Pink

Fibre #6: White Fibre #12: Aqua (Light Blue)

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Colour | blue | orange | green | brown | grey | white | red | black | yellow | violet | pink | aqua |

Sheath Colour:

The outer sheath colour is black or white

Sheath Marking:

The outer sheath is marked white color in 1 metre intervals as follows:

JIAHOME or your brand FIG GYXTC8S PART NUMBER OR YOUR ORDER NUMBER year of

Note:The sheath with color strip are available ,should be inform before production

Packing:

Fumigated stronger wooden coil or iron wooden coil idea for long distance delivery .and idea size for the optimized the container loading

Delivery length :2-6km

Main mechanical Factory Routine Test

| Parameter | Test method | Test conditions | Acceptance criteria* |

| Tensile strength | IEC 60794-1-21-E1 | As per cable maximum tensile strength (max. Working tension) in table above |

After 30 minutes the maximum strain on the fibre should not exceed 0.2% and no attenuation change throughout test |

| Crush | IEC 60794-1-21-E3 |

Short time: 10 min Long time: 120 min Load: As per maximum crush resistance in table above Number of positions: 3 adjacent sections (ensuring one over tube and one over lay reversal |

No damage to the sheath or to the core structure and no attenuation change throughout test |

| Impact | IEC 60794-1-21-E4 | Weight: 1.5 kgHeight: 1.0 m

Anvil radius: 12.5 mm Impacts: 1 |

After 5 minutes no fibre breaks, no damage to the sheath or to the core structure and no attenuation change throughout test |

| Torsion | IEC 60794-1-21-E7 | Sample length: 1 mRotation: a) 180º clockwise, b) return to starting position, c) 180º anticlockwise, d) return to starting position. Four movements constitute one cycle).

Complete 10 cycles (a to d) in one minute maximum |

During the final tenth cycle at a), c) and after completion (no rotation) check transmitting fibres. No fibre breaks, no damage to the sheath or to thecore structure and no attenuation change throughout test |

| BendBend under tension | IEC 60794-1-21- E11Concurrent to

tensile test IEC 60794-1-21-E18A |

Mandrel diameter: 30 x Cable OD Bend: 360º (1turn)Mandrel diameter: 40 x Cable OD Bend: 360º (1turn)

|

No attenuation change throughout test

After 1minutenofibre breaks, no damage to thes heath or to the core structure and no attenuation change throughout test |

| Temperature cycling | IEC 60794-1-22-F1 | Sample length: 1000 m (minimum)Temperature range: – 10 °C to +70 °C |

All optical measurements for single mode fibers performed at 1550 nm

HOT-SALE PRODUCT

Outdoor optical cable, indoor optical cable, indoor armored optical cable, air-blown optical cable, OPGW, optical jumper, etc.